years of experience

customers

maintenance-cost saved

SPECIALIZED IN

EMBEDDED C++. HIGH FREQUENCY MEASUREMENT AND DIAGNOSTICS.

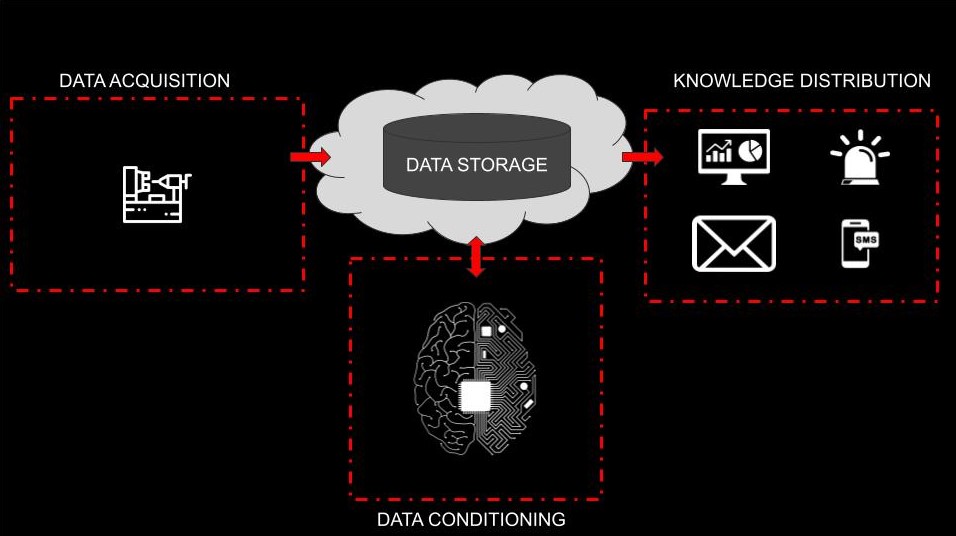

CONDITION MONITORING FOR INDUSTRY 4.0

We cater to experts in the design and manufacturing of high-end tooling machines, offering customized solutions to upgrade their machines for predictive and preventive maintenance strategies. Our systems are especially suitable for expensive equipment where the investment in monitoring systems can quickly amortize.

DATA ACQUISITION

PHYSICAL EVENTS.

We build analog front-ends for physical sensors such as

- CURRENT

- VOLTAGE

- POWER

- INFRARED CAMERAS

- ULTRASONIC VIBRATION MEASUREMENT

- FLOW MEASUREMENT

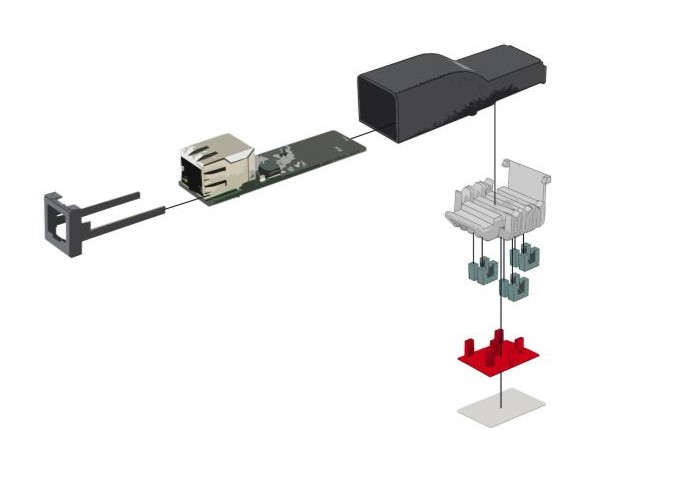

CONNECTING SENSORS TO YOUR GRID

PLUG AND PLAY.

We work with all bus-systems commonly used in the industry, such as

- ETHERNET & PoE

- CAN & LIN

- 1-WIRE

- RS232 & RS485

- LoRaWAN & USB

DATA STORAGE & DATA CONDITIONING

AI POWERED ANALYSIS. FULLY INTEGRATED.

Our in-house developed archiving-systems work hand in hand with our electronics to provide you with a comprehensive monitoring solution. To ensure seamless integration with systems like SAP or manufacturing-execution-systems, we use openly documented interfaces.

We used the following analyse methods

- FFT

- HEAT

- DQ-TRANSFORMATION & IPSA

- ISOLATION FOREST

- MACHINE LEARNING & AI

USER INTERFACES

KNOWLEDGE BECOMES POWER.

At the end of the day, no one needs data. People need knowledge to make the best possible decision. Our user interfaces bring the right information to the right place.

Some examples of our Distribution systems are

-

SMS FOR THE MAINTENANCE TECHNICIAN

-

DASHBOARD FOR THE PLANT MANAGER

-

ANALYSIS SOFTWARE FOR THE MACHINE OPERATOR

-

GREEN LIGHT FOR THE STACKLIGHT

Let's talk about innovations